The Institute of Advanced Industrial Science and Technology (AIST) in Japan recently unveiled the latest in its lineage of HRP humanoid robots. The line’s newest addition, HRP-5P, is being touted as a significant leap towards the true automation of jobsite labor.

In Professional Remodeler’s June 2018 cover story, “I, Remodeler,” we examined the early encroachment of robotics into the construction world, and learned of the engineering roadblocks keeping it from remodeling jobsites. “You don’t have assembly line repeatability in remodeling and home improvement,” said Timothy Wenhold, chief innovation officer for Power Home Remodeling Group. “We need a melding of AI and robotics.”

After five generations of HRP robots, that’s exactly what AIST has purportedly created.

“We aimed to replace heavy labor work,” the report’s authors wrote. “(HRP-5P is) a humanoid robot that combines (a) robust body and advanced intelligence, and can autonomously work with robots alone.”

“We aimed to replace heavy labor work,” the report’s authors wrote. “(HRP-5P is) a humanoid robot that combines (a) robust body and advanced intelligence, and can autonomously work with robots alone.”

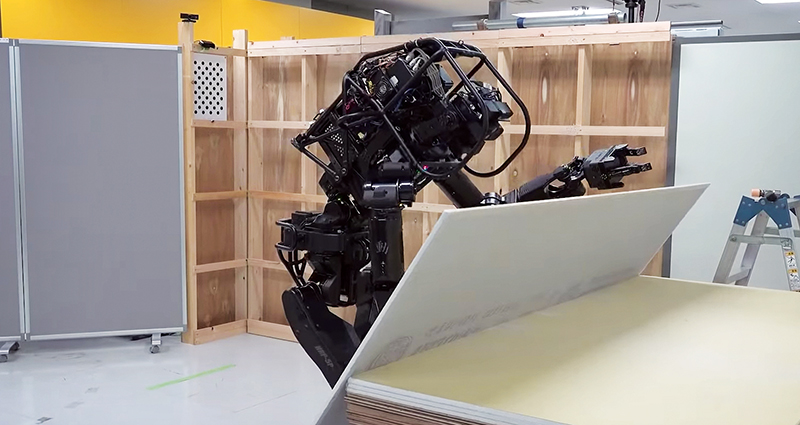

In a demonstration of HRP-5P’s capabilities, researchers had it hang drywall. It created a dimensional map of the environment; leaned on the workbench while shifting the stacked drywall to lift only one sheet; carried the sheet to the wall frame (acknowledging the surroundings); lowered the sheet against the wall; found the tools it needed to fastened the drywall; and then screwed it into the wall (while holding the furring edge for stability).

The popular argument against robotics in remodeling—apart from price, which remains and will likely persist, at least in the short term, as too high for most contractors—is that remodeling jobsites are too unpredictable to automate. HRP-5P is, at the very least, evidence to the contrary. To the robot’s builders, it’s a sign of the machine’s viability as a long-term labor analog.

“Robot intelligence research and development on the platform is aimed at autonomous replacement of various work at the site of assembly of large structure such as building, house, aircraft, and ships,” reads the report. “This will compensate for the shortage of workers, free human beings from heavy labor work, and support to focus on higher value added work.”

Add new comment

Related Stories

Business Coach Cited in Suit Against Contractor

A New England contractor faces a civil suit alleging his company’s growth was tied to a business coach with a model that “encourages fraud.”

Harvard Says Remodeling Spending Downturn to Slow

Could the drop in remodeling spending from post-COVID levels regulate soon?

Power Home Remodeling Now Offers Subsidized Childcare

The home improvement giant's move seeks to address a greater industry issue

Contractor Facing Lawsuit in ‘Major Case’ by Ohio Attorney General

An Ohio custom builder and remodeler faces a lawsuit after alleged losses exceeding $1 million

Learn from the Best in Home Improvement and Remodeling

This year’s Pinnacle Experience aims to help remodelers stay ahead of their competitors by featuring captivating keynote speakers and subject matter experts, collaborative roundtable discussions, and networking with proven players from across the country.

Registration Open for The Pinnacle Experience 2024

Register today for The Pinnacle Experience 2024 in Baltimore from June 26-28. Join the best and brightest in home improvement and remodeling for insight, advice, and relationship-building that will help you take your business to new heights.

Marvin Releases Switchable Privacy Glass Window

The privacy glass windows can be purchased from Marvin's Direct Glaze windows

Gas Ban in New Construction Considered by Chicago

The mayor-backed ordinance would impact all new construction

Working Toward Affordable, Resilient Homes

A new natural disaster protection act from NAHB aims to support hazard mitigation projects

The Remodeling Market Could Turn in Q4, Says Harvard

Repair and remodeling spending could see an uptick at the end of the year